Introduction to K24 Propane Idle Circuit

The K24 propane idle circuit is a crucial component in propane-fueled engines, especially in modified or high-performance settings. Understanding its function, design, and optimization ensures that engines run smoothly at idle, preventing common issues like stalling, rough idling, or incomplete combustion. This article provides an in-depth exploration of the K24 propane idle circuit and best practices for maintaining its optimal performance.

How the K24 Propane Idle Circuit Works

The idle circuit in a propane engine regulates the air-fuel mixture when the engine is at rest or running without load. In the K24 engine series, known for its robust performance and adaptability, this circuit plays a pivotal role. The propane idle circuit ensures that the engine receives a steady flow of propane vapor mixed with air, maintaining an efficient and stable idle.

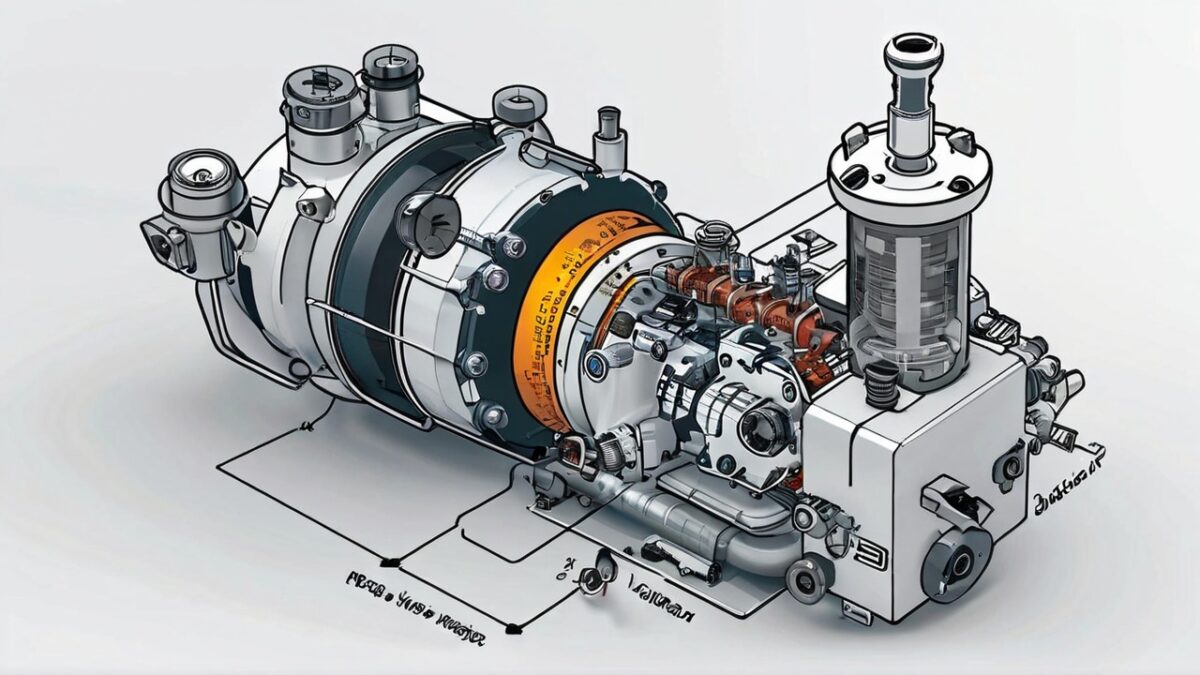

Key Components of the Idle Circuit

- Idle Mixture Screw: This screw fine-tunes the air-fuel ratio during idle. Adjusting the idle mixture screw changes the amount of fuel entering the engine, ensuring it matches the air intake for an optimal mixture.

- Idle Air Control Valve (IAC): The IAC regulates the amount of air bypassing the throttle plate. This component is essential in maintaining consistent engine RPM during idle.

- Throttle Plate and Body: While the throttle plate primarily controls engine acceleration, it also plays a role in the idle circuit. Ensuring it is clean and free from debris is crucial for proper function.

- Propane Vaporizer/Regulator: This device converts liquid propane into vapor and ensures the correct pressure for the idle circuit. A malfunctioning vaporizer can disrupt the entire idle system.

Common Issues and Troubleshooting in the K24 Propane Idle Circuit

1. Engine Stalling at Idle

One of the most common problems in the K24 propane idle circuit is stalling. This issue may occur due to a malfunctioning idle air control valve or improper adjustment of the idle mixture screw. To troubleshoot:

- Check the IAC for blockages or faults.

- Ensure the idle mixture screw is set correctly, allowing a balanced air-fuel mixture.

- Inspect the propane vaporizer for any signs of clogging or wear.

2. Rough Idle

A rough or uneven idle is often indicative of an air-fuel imbalance. This can be caused by:

- Vacuum Leaks: Inspect hoses and connections for any leaks that could lead to unregulated air entering the system.

- Dirty Throttle Body: Accumulated deposits can restrict airflow, affecting the idle.

- Faulty Sensors: The oxygen sensor and other emission control sensors should be checked to ensure they are providing accurate data for the air-fuel ratio.

3. High Idle Speed

If the engine’s idle speed is excessively high, the following areas should be evaluated:

- Stuck IAC Valve: A valve that fails to close properly allows more air into the engine, increasing the RPM.

- Throttle Position Sensor (TPS) Issues: The TPS should be calibrated correctly to reflect the true position of the throttle.

Optimizing the K24 Propane Idle Circuit

Adjusting the Idle Mixture Screw

To achieve a smooth idle:

- Warm up the Engine: Always make adjustments with the engine at normal operating temperature.

- Incremental Adjustments: Turn the idle mixture screw in small increments to fine-tune the air-fuel mixture. A slight lean (less fuel) setting typically yields a cleaner burn, while a richer (more fuel) setting may prevent misfires.

- Listen to the Engine: Adjust the screw while listening for changes in engine RPM and smoothness.

Maintaining the Idle Air Control Valve

- Regular Cleaning: Use a cleaner suitable for fuel system components to remove carbon buildup from the IAC.

- Periodic Testing: Check the IAC’s electrical connections and response using a multimeter and diagnostic tool.

Inspecting the Propane Vaporizer

The propane vaporizer must maintain a stable conversion of liquid propane to vapor. Maintenance tips include:

- Inspecting for Leaks: Check for any signs of leaking propane.

- Cleaning the Filter: Replace or clean the filter in the vaporizer as needed to prevent clogging.

- Pressure Testing: Ensure the regulator is delivering the correct pressure specified for the K24 engine.

Upgrading the K24 Propane Idle Circuit

For those seeking improved engine performance, there are upgrades available:

- Aftermarket IAC Valves: High-quality IAC valves can offer better response times and improved durability.

- Performance Vaporizers: These can provide more consistent vapor flow and pressure, ideal for high-performance applications.

- Enhanced Throttle Bodies: Upgrading to a larger or more efficient throttle body can enhance the air intake, supporting a more stable idle.

Best Practices for Maintenance

To keep the K24 propane idle circuit functioning optimally, routine maintenance is essential:

- Scheduled Inspections: Regularly inspect all hoses, connections, and components for signs of wear or damage.

- Consistent Cleaning: Prevent the buildup of deposits on the throttle body and IAC by using appropriate cleaning agents.

- Propane Quality: Use high-quality propane fuel to avoid contaminants that could impair the vaporizer and idle circuit components.

Conclusion

Understanding and maintaining the K24 propane idle circuit is vital for ensuring the engine runs smoothly at idle and performs reliably. With proper adjustments, routine inspections, and the right upgrades, the K24 engine can achieve its full potential, providing consistent and efficient performance.